Services

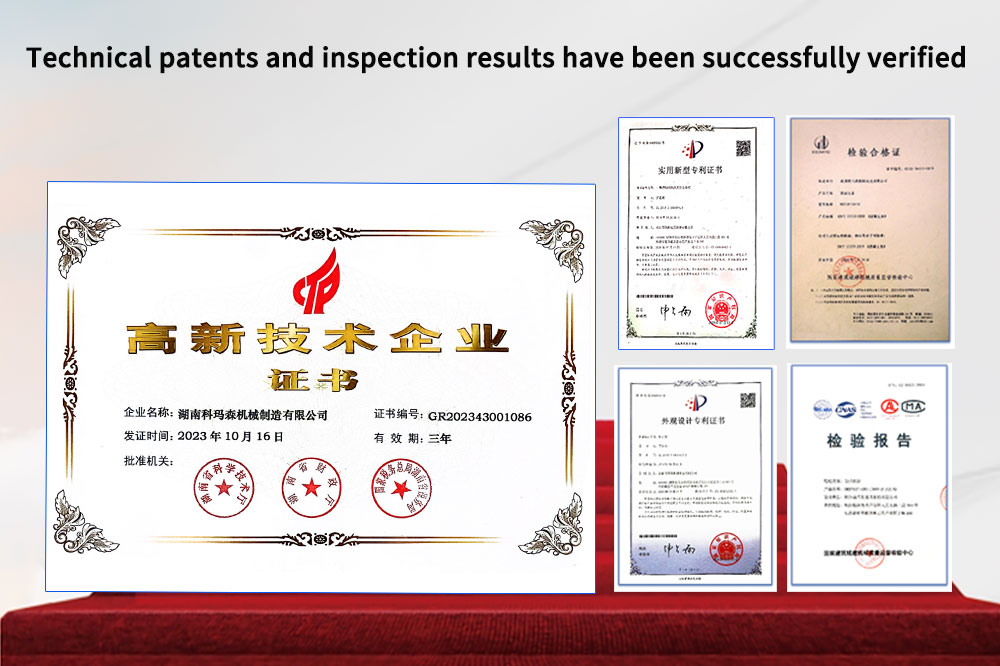

National high-tech Enterprises

Project Invention

Kemarson machinery-(Gaomasi brand) is a high-tech Enterprises, is China’s small-scale concrete trailer pump technology guide. With more than 20 patents, R & D investment intensity of more than 8% . Is the”National Construction Machinery Quality Supervision and Inspection Center” qualified products

PROJECTS

Xianyang

Construction

Sichuan

Construction

Wan You, Guangzhou

Construction

Guangzhou Metro

Construction

Hua Yuan,Yichuan

Construction

Sichuan Juma Expressway

Construction

Services

EXPLORE THE FEATURES

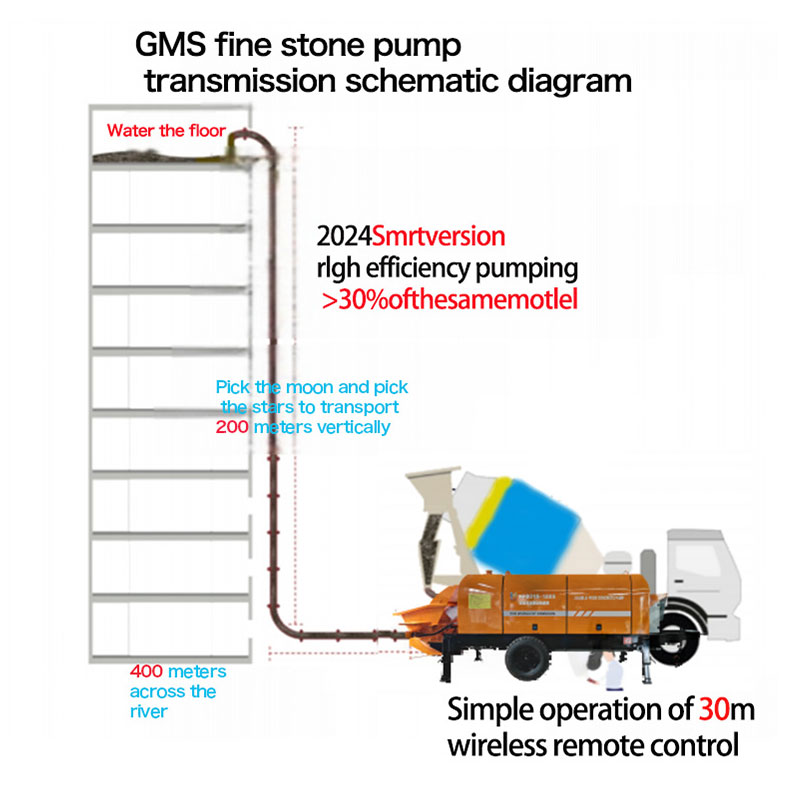

Pumping principle diagram

simple intuitive understanding of pumping principle

EXPLORE THE FEATURES

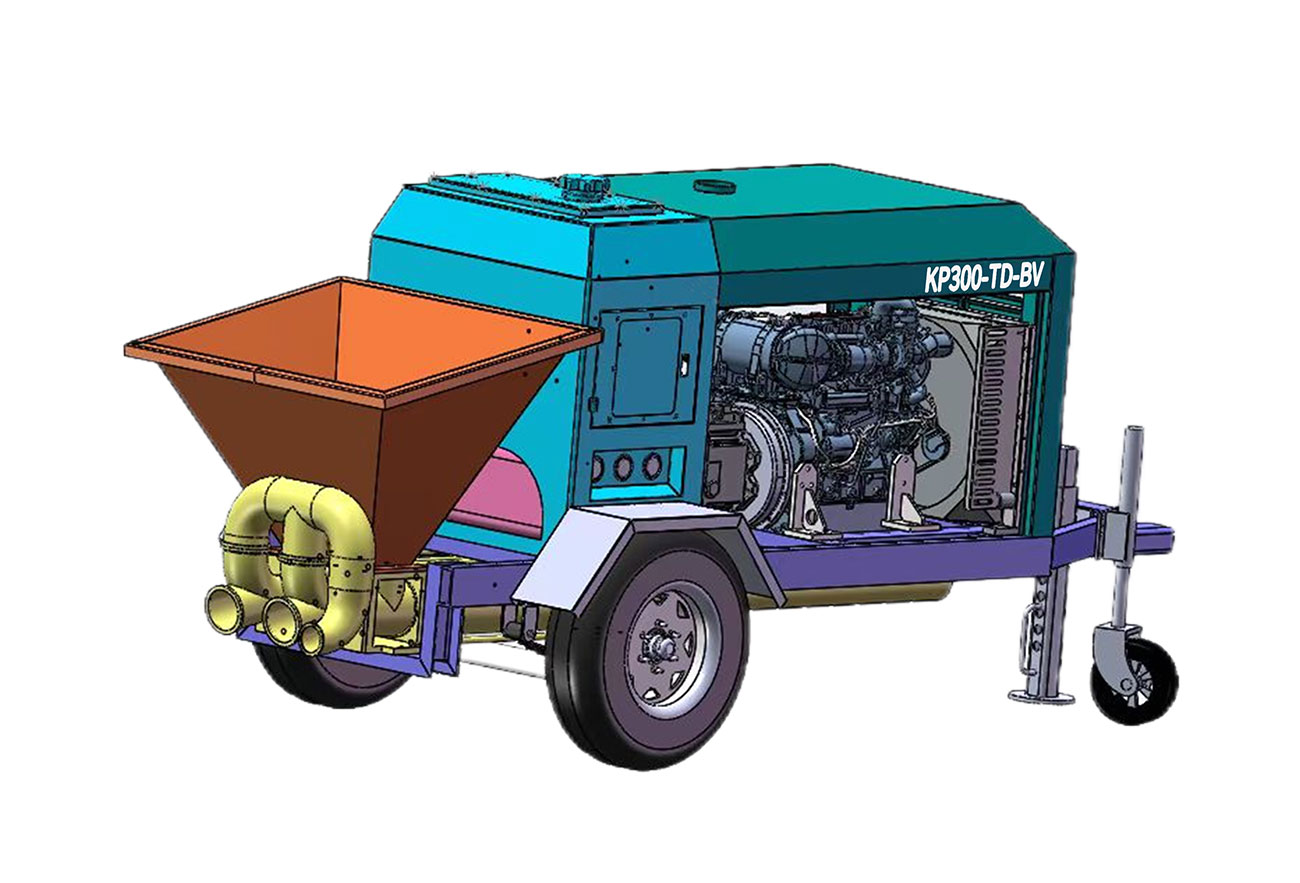

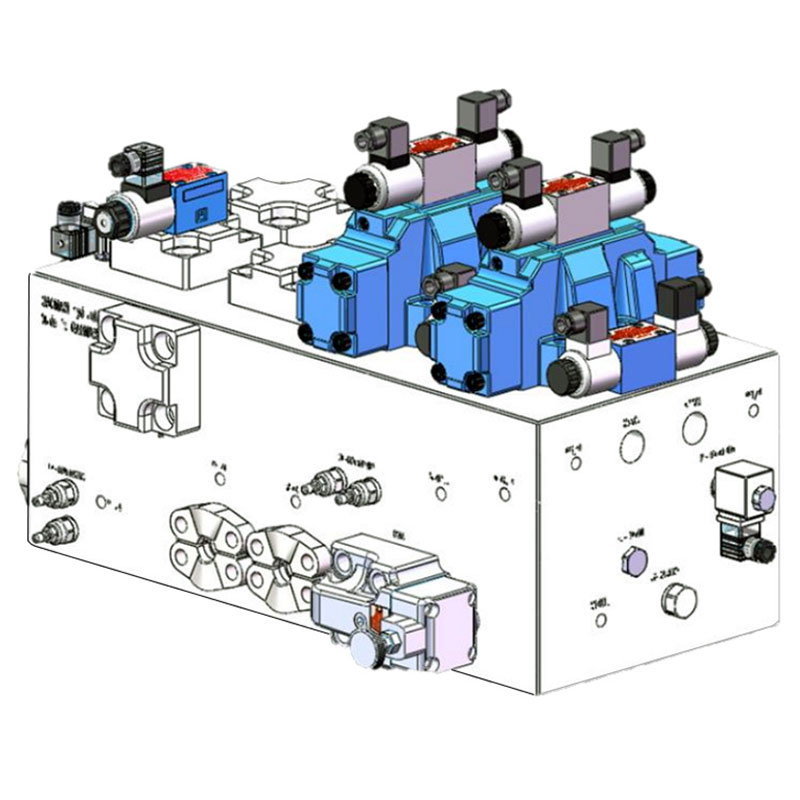

Self-developed pumping unit Assembly Pumping Unit Assembly

Pumping System Assembly is the concrete trailer pump actuator, used to transfer concrete along the pipeline to the casting site. The pumping system is composed of pumping mechanism, Hopper and s valve assembly, swinging mechanism, mixing mechanism, piping assembly and boom piping

EXPLORE THE FEATURES

Solenoid valve

electric signal through the solenoid to control the solenoid valve, solenoid valve control the direction of hydraulic oil, and then through hydraulic fluid to generate power to drive pumping action, leg action, arm action

EXPLORE THE FEATURES

R & D results of the technical team

with many successful case development experiences, such as China Railway Shield machine project-TBM concrete jetting unit, mine tank pump project, Japanese Customer Track Pump Project, North n and European version KP500 trailer pump project, etc. , excellent capability of research and development in pumping field.

PROJECTS

HAPPY

COMPLETED

COUNTRIES AND

in the high-end K-series products, we chose the high-end KP500, although the original KP400 expensive 20% yuan, but now the use of the effect has proved to be right. When facing the commodity concrete is not good (the grain is much and big, the mechanism sand or slump is not good) the KP500 material absorbency is obviously good, hits the material fast, the discharge material is full. 2 the economic value per hour than other increased by 10-15% , income-generating efficiency is high, which costs 20,000 yuan in two months to earn back. The service life of the vulnerable parts is more durable than the original model, the mechanical wear is reduced by 20% , and the later maintenance cost is lower

Northwest Shaanxi customer

willing to share their real usage experience with us. Gaoma products are slightly more expensive than their peers, but the configuration technology is significantly higher than previous machines. I learned from other friends (old customers of Gaoma) that the stability and service life are relatively long, so I chose Gaoma. Now it has finally been confirmed that my choice was right. As an investor, the joy of choosing the right product can easily infect people. Mr. Chen's genuine words also urge us to work harder in the future to make every machine better and produce products that satisfy our customers. Gaomasi sincerely hopes that users can choose their own fine stone pump products rationally and treat their investments more rationally. Because the longer the service life, better stability, and lower maintenance costs of fine stone pumps, the more cost-effective they can be. High cost-effectiveness is the guarantee of investment returns.

Xi'an customer

concrete pump often do is the work of concrete pouring, instead of the past manual construction mode, not only save costs, but also greatly enhance the efficiency of the traditional mode of work. “The advantages of the explosion-proof concrete pump in coal mines are very obvious. The function design is very user-friendly, the operation is simple, the construction is flexible, and the working efficiency is obvious to all. In a dozen hours, it can probably pour over 10,000 square meters of pavement.”. “No matter how complicated the underground situation is, it can walk freely,” Miao said. Look at a small piece of equipment, but often let a person exclaim its efficiency. In the place where the pipe, just fine-tune the reverse pump on it, the construction effect is also very good, can only point like.

African customer

Project Planning

Schematic Design: schematic design is an important stage in the design process based on user needs, including design requirements analysis, system function analysis, the use of standard technical design conditions, product price design and other processes, mainly from the analysis of demand, to determine the general object needed to realize the function and performance of the product, to decide the technical system, to realize the image of the function and performance of the product to the technical system, and to carry out the preliminary evaluation and optimization of the technical system

Preliminary Design

preliminary design is the precursor of the final product, equivalent to a sketch

Product production

product production is the design of a stage, in the technical design, preliminary design two stages later, this stage mainly through production, the designer's intention and all the design expressed.

Inspection and acceptance

1. Appearance inspection: check whether the outer packaging of the product is intact, whether the coating is damaged 2. Quantity Check: product serial number and product. Quantity check host, accessories and other equipment specifications, models, configuration and quantity, and one by one check check, check whether the random data is complete. 3. Pay attention to check the equipment serial number and factory number